Growing

First of all, specially bred seeds are planted in the nursery provided with appropriate amount of sunlight and shade. After about six months, the saplings are transplanted into the field, where the soil was preliminarily fertilized. Coffee saplings are planted in rows with the distance convenient for saplings` and soil care as well as for harvest gathering.

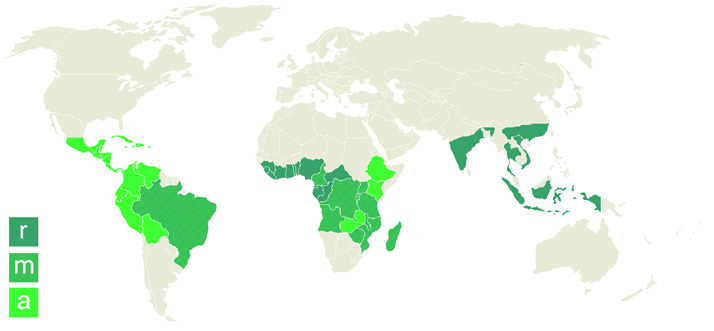

The main coffee growing areas

The fruits grow only upon condition of the year-round care that includes weeding and regular trees` treatment with fungicides and insecticides to protect them from pests and diseases, such as coffee bean borer or rust.

Young plant

Young plantYoung plant begins to bear fruit at least in two years. It is better to conduct the coffee berries collection manually removing only ripe berries one by one; that is how exactly goes when companies in Colombia, Costa Rica and other countries hire seasonal workers for this purpose.

Flowers Arabica coffee

Flowers Arabica coffeeThe berries collected manually undergo wet processing. They are placed into the wiping machine that removes most of the seed pulp. Then the seeds are put into tanks for 1-3 days, where under the influence of enzymes arising in a natural way, the remaining pulp decomposes in the process of fermentation. Next the seeds are washed in order to remove the last remnants of the pulp. Part of them is dried in the sun on the concrete terraces or drying tables, and another part is passed through the hot air dryer. The following stage deals with mechanical removing of dry peel layer that covers the grains and consists of parchment and silver sheaths. The fermentation carried out during the wet processing, along with the use of fully ripe berries, what allows to get mild coffee of excellent quality.

Fermentation

FermentationIn Brazil, which is the main country for coffee production, the most common harvesting technique is derriça. Coffee is gathered by hands, and every single berry should be picked up regardless of its degree of ripeness. Not so long ago, with the view to improve the product quality and increase the productivity some plantations started shifting their methods into mechanized and semi-mechanized. In one of them a manual air tool is used, that shakes the branches whereby berries fall to the ground. Fallen berries are raked up and sieved manually or mechanically in order to remove the leaves, dirt and sticks. Then the coffee berries are put into big 60-liter baskets. Sieved berries are washed in a concrete trough or in the machine specially designed for this purpose. During the washing ripe berries separate from old rotting dry fruits.

Drying

DryingWashed coffee is laid out on a large concrete terrace for further drying in the sun for 15-20 days. To reach an appropriate result, throughout this period the grains are turn over about every 20 minutes. Sometimes mechanical driers are used in order to accelerate the process of drying. It is necessary to monitor the level of humidity inside the grains otherwise they may get too dry, become brittle and start to crack, what will reduce their value. When the ideal humidity between 11 and 12 percent reached, the grains are being mechanically peeled. And eventually they are packed into bags and sent to the company for being classified and subjected to further processing.

News

-

-

Scientific revelation of the beneficial properties of coffee and chocolate...

Scientific revelation of the beneficial properties of coffee and chocolate...Link to Slower Aging...

read more

Information

- Locations of coffee cultivation in the past

Until the XIV century, coffee grew in Ethiopia as a wild plant. Later coffee tree was brought to the Arabian...

read more - Kinds of coffee

There are about 70 sorts of coffee trees existing nowadays, from dwarf shrubs to 10-meter giants.

read more